Factors That Affect the Installation of Prefabricated Metal Buildings

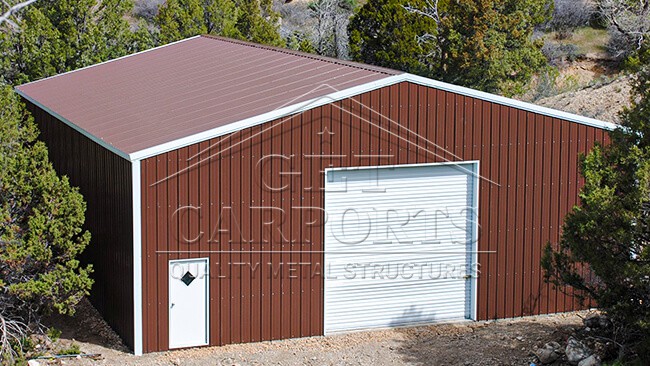

Building Dimensions (Length, Width, and Height): The size of your structure can take a great effect on the time needed to assemble your structure. While a smaller 12’W x 21’L carport might take only a few hours to assemble, a large 40’W x 60’L fully enclosed garage could take an entire day or more.

Roof Slope: The slope of your roof, just like the size dimensions of the unit, will also affect how long it takes to have your structure installed and ready-to-go. We offer different size slopes to choose from, each size affect how your building is designed and engineered.

Insulation: While insulation is optional, it will add to the timeframe of your installation process by adding an extra step. If you opt to insulate your metal structure, that doesn’t mean the entire unit has to be insulated, you can choose to have just the roof insulated or just the walls.

Anchoring System: There are different types of anchoring systems offered for different foundations, including asphalt, concrete, mobile home, and rebar anchors. The method for installing anchoring systems are unique to each type, and if you have your unit certified, more time will be required due to the need of additional anchors.

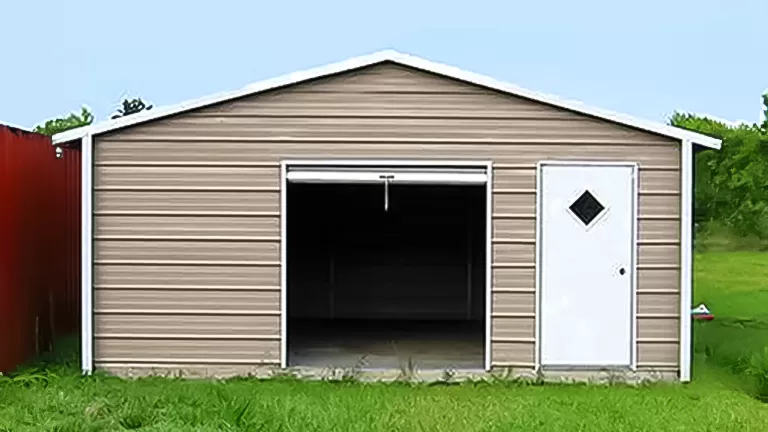

Material Handling, Unloading, and Storing: Since each steel component is unloaded and assembled manually, this will also add to the time needed for assembly. From the base rail, to the roofing system, to the bolts and screws that piece it all together, it’s all loaded and unloaded by hand; no equipment necessary.

Structural Framing: With a specific design and layout for each of our custom metal buildings, there is a certain method to installing a steel unit. There are no pieces of equipment required for the assembly process, everything is pieced together by our crews.